When you check out the steel grades, then you can find three of them. These are mostly used in product manufacturing. The carbon steel, alloy steel, and stainless steel are the top three choices.

When you check out the composition of each of these different types of steels, then you can find that each of them has different amounts of copper and iron, and there are some additional alloys in many cases.

You can check out which type of steel grade you should consider. Well, it depends on multiple factors. You have to check out the hardness, strength, toughness, durability, and many other similar factors.

Carbon Steel

Besides iron, the fundamental element of this steel is carbon. You most likely previously made sense of that much. The lower the carbon content, the higher the ductile the metal is. The higher the carbon content, the more you can heat treat and solidify the metal. Higher carbon content likewise makes it more difficult to weld.

Low Carbon Steel

It is also known as mild steel, where the carbon content is somewhere in the range of 0.05 and 0.25%, with a most extreme manganese content of 0.4%. It’s the most common sort of steel you’ll discover in applications that don’t have particular prerequisites, similar to high quality or wear resistance. This is common steel for specialists to utilize. You’ll see it in straightforward mechanical frameworks. It is anything but difficult to weld so you can get the best result as a rule, truly simple to work with.

Medium Carbon Steel

The carbon content is 0.29% to 0.54% carbon, with a manganese content of 0.6% to 1.65%. It is stronger steel with great wear resistance, but it’s somewhat trickier to shape, weld, and cut. Average carbon steels can be heat treated and tempered. If you want to learn the composition, then you can go to www.qimingmachinery.com.

High Carbon Steel

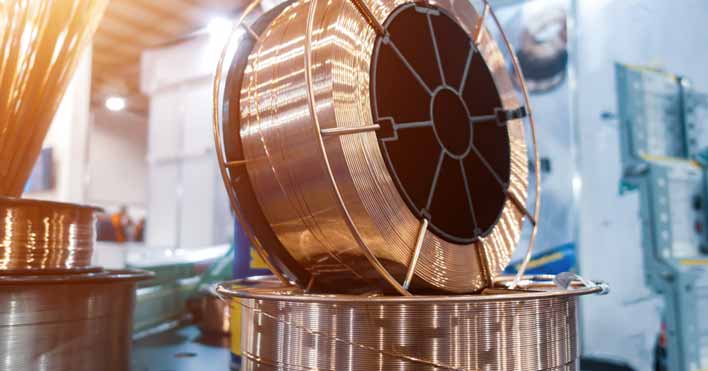

The carbon content is 0.55% to 0.95% carbon, with a manganese content of 0.30% to 0.90%. It is getting into truly particular stuff. Generally, this is possibly utilized when you truly need it, since it is difficult to work with. It’s truly strong. It is common steel to use for springs and wires since it takes a ton of pressure to get plastic twisting.

Alloy Steel

There are generally two classifications of alloy steel, which are low alloy and high alloy. Anything with an 8% alloying element is labeled as a low alloy. Anything over 8% is a high alloy. Low alloy steels are, by a wide margin, the most common. You can check out www.qimingmachinery.com to get more details.

Alloying various elements changes the properties of the steel radically. You can change the quality, hardness, and corrosion resistance by tweaking these alloying elements. You can check out some of the common alloying elements and what impact they have on the metal.

Why Should You Check The Malleability And Weldability?

Well, you might have heard about different types of things about metals. Their ability to deform into different things can be considered as a property of a metal. This property is known as malleability. The ability of the metal to be welded is known as its weldability.

So, you have to learn about its function of melting point and heat conductivity, which helps in welding metals. Every metal has its melting point, ensuring that the metals can be attached to another metal by hitting them.

So these are some of the differences that you can find between the alloy and carbon steel. You must consider such factors before you conclude. You have to differentiate between these different types of elements and materials based on the properties. Such things will help you to easily understand the major differences and ensure that you can learn some amazing facts about them.